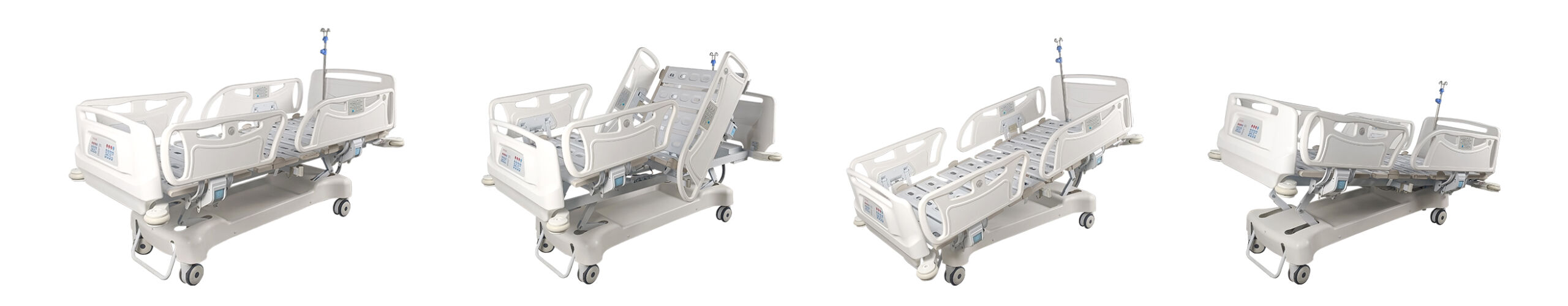

BE74 Multiple Control Panels Electrical Hospital Bed

Electrical hospital bed is a specialized bed designed for use in medical settings, such as hospitals and nursing homes, to provide enhanced comfort, support, and healthcare management for patients. Unlike traditional beds, these beds are equipped with electrical motors that enable automatic adjustments of the bed’s height, head, and foot sections. This adjustability helps accommodate various medical needs, aids in patient recovery, and facilitates easier care by healthcare professionals. Key features often include remote controls for operation by both staff and patients, safety functionalities such as emergency CPR settings to quickly flatten the bed, and lockable wheels for stability. Additional provisions like built-in side rails, IV pole attachments, and backup batteries for power outages further underscore the bed’s role in promoting patient well-being and efficient medical care.

Technical Parameter:

| External Length | 2230mm |

| External Width | 1050mm |

| Bed Height Min | 530mm |

| Bed Height Max | 770mm |

| Mattress Platform | 1925*900mm |

| Safe Working Load | 250kg |

| Back-rest | 75°±10° |

| Knee-rest | 35°±10° |

| Trendelenburg | 12°±3° |

| Reverse Trendelenburg | 12°±3° |

Technical Configuration:

| Linear Motor | 4pcs |

| 6” Double-Side Caster | 4pcs |

| Central Locking Pedal | 1pc |

| PP Bed End | 1set |

| PP Side Rail | 1set |

| IV Pole | 1pc |

| IV Pole Prevision | 6pcs |

| Drainage hook | 2pcs |

| Built-in Angle Indicator | 4pcs |

| Bumper Wheel | 4pcs |

| Built-in Control Panel | 5pcs |

| Back-up Battery | 1pc |

| Manual CPR | 1set |

Optional:

- Weighing System

- Nurse Controller

- Night Light

- Monkey Pole

- Electric CPR

- Mattress

- X-ray Translucent Platform (Back Section)

Product Introduction:

Quality Control:

- Technology: The technology integrated into electrical hospital bed represents a significant advancement in medical care equipment, focusing on both functionality and patient comfort. A key feature of these beds is the use of robotic arm 360° welding technology, which ensures a strong, flawless construction. This technique allows for precision in joining parts, leading to increased durability and safety. Additionally, the beds are treated with a steel-plastic spraying technology, which not only enhances their visual appeal with a flawless finish but also provides a protective coating that makes them more resistant to corrosion and wear. The structural components, made from seamlessly joined cold-pressed steel plates and steel tubes, contribute to the bed’s overall sturdiness and reliability. These technological enhancements ensure that electrical hospital beds are not only aesthetically pleasing but also robust and suitable for intensive use in medical settings.

- Safety Standard: Electrical hospital bed is held to stringent safety standards to ensure they meet the critical needs of patient care environments. They are compliant with ISO 13485:2016, which is a specific certification for medical device quality management systems. This standard ensures that the beds are consistently designed, manufactured, and distributed in a way that prioritizes safety and efficacy. Additionally, these beds adhere to ISO 9001:2015, which focuses on general quality management systems and guarantees that the manufacturing processes are efficient and controlled to enhance product quality and reliability. Furthermore, the inclusion of CE certification indicates that the electrical hospital beds conform to European health, safety, and environmental protection benchmarks. Together, these certifications demonstrate a commitment to high safety standards, ensuring that the beds provide not only comfort and functionality but also robust safety measures to protect patients and healthcare providers alike.

- Design: The design of the electrical hospital bed incorporates several thoughtful features to enhance both usability and hygiene. A notable aspect is the O-shaped support structure, which optimizes the bed’s strength and stability while supporting multiple functionalities. This streamlined design not only contributes to a more aesthetically pleasing appearance but also minimizes crevices where bacteria can accumulate, thus improving the overall cleanliness and infection control around the patient’s environment. Additionally, at the foot of the bed, a control panel with integrated user instructions is strategically placed. This design is particularly beneficial as it guides medical staff on the correct usage of the bed’s various functions, reducing unnecessary trials and making operation clearer and more convenient. Such features demonstrate a deep understanding of the needs within a healthcare setting, ensuring that the bed enhances care delivery and maintains high standards of hygiene.

Framework:

- Platform: The platform of the electrical hospital bed is ingeniously designed with a segmented approach, specifically divided into ten sections. This multi-segment configuration allows for targeted pressure relief in specific areas of the patient’s body, significantly reducing the risk of pressure ulcers, a common concern for patients who spend extended periods in bed. Each segment can be individually adjusted to cater to the unique needs of different body parts, enhancing both comfort and support for the patient. Furthermore, the bed surface panels are finished with steel-plastic spraying, which not only provides a durable, easy-to-clean surface but also contributes to the overall hygiene and maintenance of the bed. This thoughtful design element ensures that the bed can be effectively sanitized, maintaining a safe and clean environment for both patients and healthcare providers.

- PP Bed End: The PP bed end of the electrical hospital bed is meticulously crafted using a single-step blow molding process with polypropylene (PP) material, resulting in a sleek, flawless appearance that is both aesthetically pleasing and functional. This material is chosen for its excellent properties, including resistance to corrosion and high temperatures, ensuring durability and longevity under the rigorous demands of a hospital environment. The bed end is equipped with a safety lock mechanism to prevent accidental detachment, enhancing the safety of both patients and caregivers. Its detachable design allows for quick adjustments in emergency situations, providing flexibility and rapid response capabilities. Additionally, the bed end incorporates an embedded control panel, complete with an adjacent user manual. This setup facilitates easy access to control all functions of the bed, making it convenient and user-friendly for medical staff to operate while minimizing the need for extensive training or reference to external resources.

- PP Side Rail: The PP side rail of the electrical hospital bed is crafted using a one-step blow molding process from polypropylene (PP) material, which achieves a robust, flawless, and aesthetically pleasing finish. This material is particularly chosen for its excellent properties such as corrosion resistance and high-temperature tolerance, making it ideal for the demanding hospital environment. The side rails feature a lift-and-lower design that facilitates patient mobility, medical care, and the safe transfer of patients. To enhance safety, the rails are equipped with damping mechanisms to prevent sudden drops that could potentially cause injury. Each rail also includes an embedded angle indicator, which aids in adjusting the bed to the precise angles required for various medical needs or patient comfort. Furthermore, the back panel part of the side rails incorporates embedded control panels on both the inside and outside, allowing for easy and convenient adjustment of the bed’s features from any side, thereby improving accessibility and usability for both healthcare providers and patients.

- Base Cover: The base cover of the electrical hospital bed is thoughtfully designed with a dust cover, which serves multiple essential functions. This feature not only enhances the overall stability of the bed but also plays a crucial role in maintaining hygiene. By shielding the underside of the bed from dust and debris, the cover effectively reduces the accumulation of bacteria, which is particularly important in a hospital setting to minimize the risk of infections. The inclusion of this cover also facilitates easier cleaning, allowing maintenance staff to efficiently manage and maintain cleanliness without the need to access hard-to-reach areas under the bed. Moreover, the design of the base cover contributes to the bed’s aesthetic appeal, ensuring that the bed fits seamlessly into the clean and professional look of healthcare environments. This combination of functionality, hygiene, and design makes the base cover a vital component of the electrical hospital bed.

Function:

- Trendelenburg/Reverse Trendelenburg: The electrical hospital bed is equipped with both Trendelenburg and Reverse Trendelenburg positioning capabilities, enhancing its versatility in patient care. These functions allow the bed to tilt up to 12°±3°, providing a significant range of adjustability to meet various clinical needs. The Trendelenburg position involves tilting the bed such that the patient’s feet are elevated higher than the head, which can be critical in situations like shock or other conditions where improving blood flow to the brain is necessary. Conversely, the Reverse Trendelenburg position raises the head higher than the feet, which is beneficial for patients with respiratory issues, aiding in easier breathing, or for those who require reduced esophageal reflux. These positioning features are controlled electronically, ensuring smooth and precise adjustments that can be easily executed by medical staff, thereby enhancing patient comfort and facilitating effective treatment and care.

- Back Section Adjustment: The electrical hospital bed features an adjustable back section that significantly enhances patient comfort and supports a variety of medical needs. This section can be raised to an angle of up to 75°±10°, allowing for a wide range of positions. Such adjustability is crucial for patients who need elevation of the upper body either for respiratory ease, such as in cases of dyspnea or when receiving respiratory therapy, or for lifestyle reasons, such as eating, reading, or watching television. The precise control over the back angle also assists in clinical procedures and examinations, facilitating access for healthcare providers. This functionality is controlled electronically, ensuring smooth, quiet adjustments that minimize discomfort for the patient. The ability to adjust the back section easily and accurately is an essential feature that enhances both the functional and comfort aspects of patient care in a hospital setting.

- Leg Section Adjustment: The electrical hospital bed includes a crucial feature for leg section adjustment, which significantly contributes to patient comfort and therapeutic needs. This adjustment allows the leg section of the bed to be raised up to an angle of 35°±10°. Elevating the legs can be particularly important for various medical conditions, including reducing swelling, improving circulation, and preventing venous stasis, which are common concerns for immobilized patients. The ability to adjust the leg section helps in creating ergonomic positions that can aid in recovery and provide comfort during long periods of bed rest. Additionally, this functionality can be used to support specific post-surgical care requirements or to enhance comfort during procedures such as dressing changes or wound care. The leg section is controlled through motorized systems, ensuring smooth and gentle adjustments that are safe for the patient, thereby minimizing any potential discomfort or risk during movement. This feature underscores the ICU bed’s design emphasis on adaptability and patient-centered care.

- Whole Bed Height Adjustment: The electrical hospital bed offers an essential feature of whole bed height adjustment, allowing the bed’s height to be varied between 530mm and 770mm. This adjustable height capability is crucial for both patient comfort and healthcare provider accessibility. For patients, the ability to lower the bed can facilitate easier entry and exit, reducing the risk of falls and injuries, which is particularly important for those with limited mobility. Conversely, raising the bed to a higher position can provide easier access for medical staff during examinations, treatments, or while performing surgical procedures, thereby reducing strain and enhancing ergonomic comfort for caregivers. The height adjustment is managed electronically, ensuring smooth, stable transitions that enhance safety for the patient while offering flexibility in the care environment. This functionality not only aids in patient handling but also supports various clinical needs, making it a pivotal feature in optimizing care delivery in hospital settings.

Accessory Detail:

- Linear Motor: The electrical hospital bed is equipped with four high-quality imported linear motors that drive the various adjustments and movements of the bed, including the adjustments for height, back section, and Trendelenburg positions. These motors are specifically selected for their reliability and efficiency. One of the key features of these linear motors is their ability to operate quietly, ensuring that the bed adjustments do not disturb the patient’s rest or create a noisy environment, which is crucial in maintaining a calm and healing atmosphere in healthcare settings. The smooth and silent operation of these motors enhances patient comfort and provides a better experience for both patients and healthcare providers. Additionally, the use of multiple motors allows for more precise and independent control of each bed function, improving the functionality and responsiveness of the bed to meet specific clinical needs.

- 6’’ Caster: The electrical hospital bed is fitted with high-quality casters, specifically designed to meet the demanding requirements of medical environments. Each caster features a 150mm dual-sided wheel made from TPE (Thermoplastic Elastomer) material, known for its durability and wear resistance. This material selection ensures that the wheels can withstand tens of thousands of braking actions without significant wear, contributing to the bed’s longevity and reliability. Additionally, the TPE material is resistant to corrosion, making the casters suitable for various medical settings where exposure to different substances and frequent cleaning are common. The casters are also designed for quiet operation, which is crucial in maintaining a peaceful atmosphere conducive to patient recovery. The inclusion of an anti-wrap feature prevents cords and other debris from becoming entangled in the wheels, ensuring smooth and uninterrupted mobility. This combination of durability, corrosion resistance, and thoughtful design features makes these casters an integral part of the bed’s overall functionality and ease of use in healthcare facilities.

- Bumper Wheel: The electrical hospital bed is equipped with strategically placed bumper wheels at each of its four corners, which protrude slightly beyond the frame of the bed. These bumpers are crafted from a soft plastic material, designed to absorb the impact during collisions. This feature is particularly important in a hospital setting where beds are frequently moved through hallways and into elevators, increasing the risk of contact with walls and door frames. The soft plastic material of the bumpers effectively minimizes the force of such impacts, thereby reducing damage to both the hospital infrastructure and the bed itself. Furthermore, the presence of these bumpers helps shield patients from sudden jolts or shocks that could occur from these collisions, enhancing patient comfort and safety. This thoughtful design element underscores the commitment to quality and patient-centered care found in the construction of modern hospital beds.

- Angle Indicator: The electrical hospital bed is thoughtfully equipped with angle indicators on each of its side rails, a feature that greatly assists medical staff in their daily care routines. These indicators play a crucial role by enabling healthcare providers to accurately observe and adjust the bed’s inclination to specific angles, thereby ensuring precise positioning according to the therapeutic needs or comfort requirements of the patient. Each angle indicator is designed with clear and distinct markings, making it easy for staff to quickly discern and set the desired tilt of the bed. This functionality is particularly valuable during procedures that require exact positioning, such as during recovery from surgery or when managing patients with respiratory issues. The presence of these angle indicators on each rail enhances the efficiency of care delivery, allowing for quick adjustments while reducing the need for guesswork and frequent repositioning, ultimately contributing to better patient outcomes and a smoother operational flow within medical facilities.

- Central LockingPedal: The electrical hospital bed is equipped with an integrated central locking pedal located at the foot of the bed, a design feature that enhances both safety and convenience. This central locking system allows for a quick and efficient means of securing the bed in place. When the pedal is pressed down, it activates the locking mechanism on all wheels simultaneously, ensuring that the bed is firmly fixed in position and cannot be moved. This is crucial for maintaining stability during medical examinations, treatments, or when the patient needs to remain in a fixed position without any risk of unintended movement. Conversely, lifting the pedal disengages the locks, making the bed mobile again. This system allows healthcare providers to easily transition the bed between stationary and movable states, facilitating patient transport and room rearrangements with minimal effort. The central location of the pedal and its ease of operation ensure that the bed can be quickly and safely secured or released, providing a practical solution that meets the dynamic needs of a hospital environment.

- IV Pole&IV Pole Prevision: The electrical hospital bed is thoughtfully equipped with an IV pole and multiple IV pole previsions to meet the diverse medical needs of patients. The IV pole itself is constructed from durable stainless steel, ensuring longevity and resistance to wear and tear. It features an adjustable height mechanism, allowing it to be set at the optimal level for each patient’s specific requirements, thereby enhancing the efficiency of fluid administration. Additionally, the pole is equipped with four hooks, providing ample capacity for multiple IV bags or other necessary medical equipment. To further enhance its usability, previsions for attaching the IV pole are strategically placed not only on each of the four bumper wheels but also at the central points on both the left and right side edges of the bed. These multiple attachment points allow for flexible positioning of the IV pole based on the patient’s position and the specific medical procedures being performed. This design consideration ensures that the IV setup can be easily accessed by healthcare providers from any side of the bed, improving the delivery of care and accommodating a wide range of clinical scenarios.

- Control Panel: The electrical hospital bed is thoughtfully equipped with advanced control panels integrated into both the inner and outer sides of the guardrails at the backrest, providing easy access to the total power switch and adjustments for all functionalities such as bed height and angle settings. An additional specialized control panel embedded in the footboard offers a critical safety feature: the ability to lock individual functions. This prevents accidental adjustments that could harm the patient or interfere with treatments, allowing medical staff to secure certain settings for therapeutic procedures or recovery stability. These control panels enhance the bed’s functionality and safety, making it an essential tool in providing effective patient care in hospital settings.

- Back-up Battery: The electrical hospital bed is equipped with a back-up battery system designed to ensure continuous functionality during emergencies, such as power outages or when the bed needs to be moved to an area without an immediate power supply. This feature is crucial for maintaining the adjustability of the bed’s various positions—height, tilt, backrest, and leg elevation—even without a direct electrical connection. The back-up battery activates automatically when the main power supply is interrupted, allowing healthcare providers to continue administering necessary adjustments and care without disruption. This not only aids in patient comfort and safety but also ensures that critical medical procedures can proceed uninterrupted. The inclusion of a back-up battery in the design of hospital beds reflects a commitment to reliability and continuous care, even under challenging conditions.

- Manual CPR: The electrical hospital bed is fitted with a crucial safety feature, the manual CPR (Cardiopulmonary Resuscitation) button, strategically located on the lower side of the bed for quick and easy access. In the event of a cardiac emergency, pressing this button causes the bed’s surface to immediately revert to a flat position, which is the optimal configuration for performing CPR and other life-saving interventions. This rapid transformation is vital, as it allows healthcare providers to commence resuscitative efforts without delay, significantly enhancing the patient’s chances of recovery. The inclusion of a manual CPR function not only increases the bed’s safety features but also ensures that it can support critical care procedures swiftly and effectively, making it an indispensable asset in emergency medical scenarios.

PP SIDE RAIL

Made of PP material, one-time blow molding, beautiful, flawless, anti-corrosion and high temperature resistant. Liftable design is convenient for patient activities, medical care or patient transfer. Damping guardrails prevent sudden and unexpected drops from causing harm. Each guardrail comes with an embedded angler. There are embedded control panels on both sides of the back panel guardrail.

BUILT-IN ANGLE INDICATOR

Distributed on each guardrail, it can help medical staff observe the inclination angle of the hospital bed to facilitate more precise care. The scale is clear and easy to distinguish.

BASE COVER

There is a dust cover at the bottom of the bed, which increases stability and reduces bacterial residue at the bottom of the bed, making it easy to clean and more beautiful.

BUMPER WHEEL

Located at the four corners of the bed, they protrude from the bed body and play a protective role. Made of soft plastic material, it can effectively absorb the impact force during impact, reduce the impact on the wall and bed, and keep the patient away from shock.

CENTRAL LOCKING PEDAL

Located at the end of the bed, the integrated central control pedal facilitates overall braking. When the foot pedal is depressed, the entire bed is firmly fixed in place and cannot move, making it very safe. The bed can move again when the footrest is lifted.

PP BED END

Made of PP material, one-time blow molding, beautiful, flawless, anti-corrosion and high temperature resistant. With safety lock, it will not be accidentally detached. Detachable design allows quick adjustment in emergency situations. The footboard has an embedded control panel with an instruction manual next to it to control all functions of the bed.

MANUAL CPR

The manual CPR button is located under the side of the hospital bed. When pressed, the bed panel can immediately return to its original flat state for cardiopulmonary resuscitation and other medical measures. This feature greatly enhances the safety of the hospital bed.

Reviews

There are no reviews yet.