ORP-PT05S Transport Stretcher Beds for Hospital

Stretcher beds are indispensable tools in the healthcare industry, designed to transport patients safely and comfortably within medical facilities. These beds are typically built with a sturdy, lightweight frame, often made from materials like aluminum or steel, to ensure durability and ease of maneuverability. Key features include adjustable side rails for patient safety, a multi-position backrest for comfort, and smooth-rolling wheels equipped with secure braking systems. Many stretcher beds also come with enhancements such as retractable IV poles, oxygen cylinder holders, and storage trays for personal belongings and medical supplies. The inclusion of a central locking pedal system allows healthcare providers to easily lock and unlock the wheels, facilitating safe transfers and positioning. The mattresses on these beds are designed with patient comfort in mind, featuring soft sponge cores and waterproof, breathable covers.

Technical Parameter:

| Bed Height Min | 524mm |

| Bed Height Max | 845mm |

| Overall Size (L*W) | 1970*685mm |

| Platform Size (L*W) | 1903*650mm |

| Safe Working Load | 250kg |

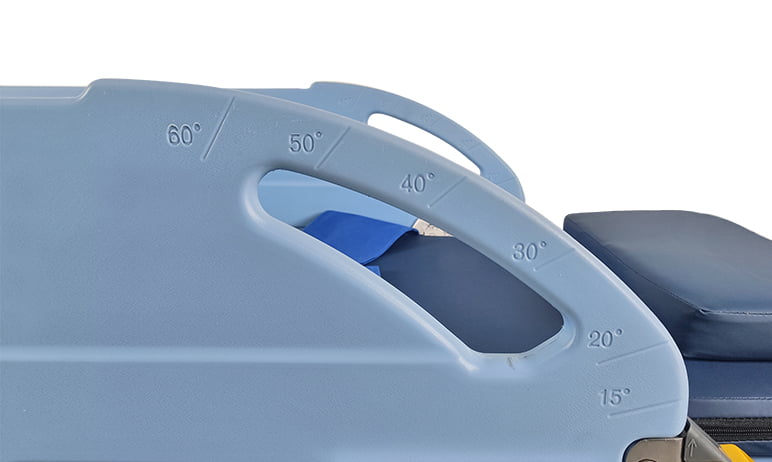

| Back-rest | 75°±10° |

| Net Weight | 75kg |

Technical Configuration:

| Back-Rest Gas Spring | 1pc |

| 6’’ Double-Side Casters | 4pcs |

| Central Locking Pedal | 4pcs |

| Directional Wheel Release Handle | 1pc |

| Directional Wheel | 1pc |

| PP Side Rail | 4pcs |

| Oxygen Cylinder Holder | 1set |

| Metal Hand Crank | 1pc |

| IV Pole | 1set |

| IV Pole Prevision | 4pcs |

| Mattress | 1pc |

| Safety Strap | 2pcs |

Product Introduction:

Quality Control:

- Technology: Stretcher beds, essential tools in medical and emergency response settings, have seen significant advancements in technology, enhancing both their functionality and durability. One pivotal innovation is the use of one-step injection molding techniques, which allow for the creation of stretcher beds in a single, continuous process. This method not only streamlines manufacturing but also ensures uniformity and reduces potential weaknesses in the structure. High-quality materials are carefully selected to optimize weight, strength, and resistance to environmental factors, ensuring the beds can withstand rigorous use in varied conditions. Additionally, manufacturers have adopted 360° no blind spot welding technology, which reinforces the bed’s integrity by eliminating weak points typically left by conventional welding techniques. This method provides a seamless and robust joinery across all parts of the stretcher, significantly enhancing its overall strength and lifespan. Together, these technological advancements make modern stretcher beds more reliable, robust, and capable of handling the demands of medical care in diverse scenarios.

- Safety Standard: Stretcher beds are subject to rigorous safety standards to ensure they are safe and effective for both patients and medical personnel. Key among these standards are ISO 13485:2016 and ISO 9001:2015 certifications. ISO 13485:2016 is specifically tailored for medical device manufacturers, focusing on the consistent design, development, and production of medical devices that meet regulatory requirements. ISO 9001:2015, on the other hand, sets criteria for a quality management system, emphasizing customer satisfaction and continual improvement across various industries, including healthcare. Additionally, stretcher beds often carry CE certification, which is crucial for products sold within the European Economic Area (EEA). This certification indicates that the stretcher beds meet EU safety, health, and environmental protection requirements, providing further assurance of their quality and safety. Together, these certifications form a robust framework that manufacturers must adhere to, ensuring that the stretcher beds used in hospitals and emergency settings are reliable, durable, and safe for every use.

- Design: The design of stretcher beds incorporates several thoughtful features aimed at enhancing usability and safety, with clear arrow symbols on the stretcher body being a notable example. These arrows are strategically placed to guide users through the correct steps for operating the stretcher, such as unfolding, adjusting, and locking mechanisms. This intuitive design element helps ensure that medical personnel can quickly and safely set up or modify the stretcher, even under high-pressure situations common in emergency environments. The inclusion of these visual cues not only reduces the risk of incorrect usage, which could potentially harm patients or hinder medical interventions, but also speeds up the response time by making the operation of the stretcher more straightforward and efficient. This focus on user-friendly design is critical in medical settings, where every second counts and ease of use can significantly impact the outcome of patient care.

Function:

- Back Section Adjustment: The back section adjustment mechanism on stretcher beds is ingeniously designed for both simplicity and efficiency, ensuring that caregivers can easily reposition patients to enhance comfort and meet clinical requirements. This adjustment is typically achieved by lifting a handle located under the head of the back section. Once the handle is engaged, the user can press and lift the back section upwards to the desired angle, with a range allowing for an approximate elevation of 75°±10°. This flexibility in positioning is crucial for various medical procedures and patient needs, such as improving breathing, facilitating feeding, or simply enhancing comfort during prolonged periods of immobility. The handle mechanism is designed to be intuitive and secure, ensuring that once the desired position is achieved, it is maintained stably without any risk of accidental movement, thus prioritizing patient safety and comfort. This feature reflects a thoughtful approach to the design of stretcher beds, emphasizing functionality and user-friendliness in critical care settings.

- Whole Stretcher Height Adjustment: The height adjustment feature of stretcher beds is a critical component that enhances both patient care and caregiver ergonomics. This functionality is typically controlled by a crank located at the end of the stretcher, allowing for smooth and precise adjustments. The platform’s height can be varied between 524mm and 845mm, a range that accommodates various medical scenarios, from patient transfer to surgical procedures. This adjustability is crucial for aligning the stretcher with other medical equipment, such as operating tables and hospital beds, facilitating easier and safer patient transfers. By adjusting the height, caregivers can position the stretcher at an optimal level, reducing the risk of back strain and other injuries associated with lifting or moving patients. This feature not only enhances the safety and comfort of patients during movements but also significantly aids in the ergonomic efficiency for medical personnel, contributing to a more effective healthcare environment.

Accessories Detail:

- Caster: The casters on stretcher beds are meticulously engineered to ensure smooth mobility, durability, and safety in various healthcare environments. Typically, these casters feature a robust diameter of 150mm, which provides a stable and smooth ride over different floor types, including transitions between elevators and hallways. The double-sided wheel design enhances maneuverability, allowing for easy steering and positioning of the stretcher. Made from corrosion-resistant and wear-resistant materials, the casters are built to withstand the rigorous demands of a medical setting, including frequent exposure to cleaning agents and variable environmental conditions. Additionally, these wheels incorporate an anti-winding design, preventing debris, wires, and other common floor entanglements from hindering movement. This thoughtful integration of features ensures that the stretcher can be moved with minimal effort, reducing fatigue for healthcare workers and increasing comfort and safety for patients during transport.

- PP Side Rail: The side rails on stretcher beds play a crucial role in enhancing patient safety and facilitating medical procedures. These multi-functional rotary PP (polypropylene) side rails are designed with versatility and practicality in mind. They can be fully extended and laid out flat to align with an adjacent bed, acting as a transfer board. This feature significantly simplifies the process of moving patients between the stretcher and the bed, ensuring a smooth, quick, and safe transfer, which is particularly beneficial in minimizing patient discomfort and strain for healthcare providers. Additionally, these side rails can be securely fixed at a horizontal level, providing a stable platform where a patient’s arm can be comfortably rested for the administration of IVs or other treatments. This dual functionality not only optimizes the use of space and equipment in busy medical settings but also enhances patient care by facilitating both mobility and treatment accessibility.

- Central Locking Pedal: The central locking pedal system on stretcher beds is ingeniously designed to enhance both safety and maneuverability in a medical setting. Each stretcher is equipped with four central locking pedals, strategically positioned for easy access by medical staff. To ensure the stretcher remains stationary, a user simply presses the red pedal, which activates the overall braking system, securely locking all wheels and stabilizing the stretcher. This is particularly critical during medical examinations, treatments, or when the stretcher must remain immobile in a precise location. Conversely, to move the stretcher, the green pedal is pressed, releasing the brakes and allowing for smooth and effortless transportation. This simple color-coded system—red for stop, green for go—makes operation intuitive, reducing the potential for errors during critical moments. The presence of four pedals, one at each corner of the stretcher, ensures that the brakes can be easily accessed and activated from any side, greatly enhancing convenience and efficiency for medical personnel as they maneuver through the fast-paced hospital environment.

- Metal Hand Crank: The metal hand crank on stretcher beds is a critical feature designed for ergonomic and precise height adjustment, catering to various medical scenarios and patient needs. To operate, the user simply turns the crank; rotating it clockwise causes the bed board to rise, while turning it anticlockwise will lower it. This mechanism allows healthcare providers to easily adjust the stretcher height to ensure optimal alignment with other medical equipment, facilitate patient transfer, or adjust the bed to a comfortable height for medical examinations and treatments. The hand crank itself is made from durable metal, ensuring it can withstand the frequent adjustments and the rigors of a busy medical environment without failing. This simple yet effective system provides a reliable method of height adjustment that is both intuitive and accessible, making it an essential component of the stretcher bed’s functionality.

- Base: The base of stretcher beds is thoughtfully designed not only to provide stability and support but also to enhance functionality with the inclusion of an integrated utility tray. This feature is especially useful in busy medical settings where efficiency and organization are paramount. The utility tray serves a dual purpose: it offers a convenient storage solution for the patient’s personal belongings, ensuring that items such as glasses, books, or mobile phones are safely stored and easily accessible. Additionally, it is used for holding essential medical supplies close at hand, such as gloves, masks, or small medical instruments, facilitating quick access for healthcare providers. This integrated approach not only maximizes the use of space but also contributes to a more organized and streamlined care environment, reducing clutter around the patient’s bed and minimizing the risk of lost belongings or misplaced equipment.

- Platform: The platform of stretcher beds is designed with both hygiene and durability in mind, utilizing an integrally blow-molded PP (polypropylene) bed board. This manufacturing technique ensures that the bed board is a single, cohesive unit without seams or joints, which can trap dirt and pathogens. The surface of the PP material is smooth and non-porous, making it exceptionally easy to clean and disinfect. This is crucial in medical environments where maintaining sterility can prevent cross-contamination and infection. Additionally, polypropylene is known for its resistance to chemical damage and physical impact, ensuring that the bed board remains in excellent condition even under the rigorous use typical in healthcare settings. The choice of material and design not only enhances patient safety through improved infection control but also increases the longevity of the stretcher bed, making it a cost-effective solution for medical facilities.

- Directional Wheel with Control Handle: The directional wheel system on stretcher beds incorporates a highly innovative feature: a retractable 5th wheel. Positioned at the center of the stretcher’s base, this additional wheel plays a crucial role in enhancing maneuverability and control. When deployed, the 5th wheel lifts slightly off the ground, allowing for effortless directional movement and significantly improved cornering capabilities. This is particularly beneficial in tight or crowded hospital corridors and elevators, where precise movements are necessary. The 5th wheel’s design facilitates smoother transitions and sharper turns without the need for excessive force or awkward handling, thus reducing the physical strain on healthcare workers and increasing the comfort for the patient during transport. When not required, the wheel can be easily retracted, allowing the stretcher to rest stably on its four primary wheels. This versatile system ensures that stretcher beds can be adapted to various hospital environments and patient needs, making them an essential tool in medical logistics.

- IV Pole: The IV pole on stretcher beds is an essential component designed to support intravenous treatments efficiently while ensuring patient mobility. Constructed from stainless steel, the body of the IV pole offers durability and resistance to corrosion, important factors in maintaining hygiene and longevity in a medical environment. This pole features a height-adjusting knob, allowing medical staff to easily customize the pole’s height to suit the patient’s needs, whether they are sitting up or lying down. This adjustable feature enhances patient comfort and ensures the effective delivery of fluids or medications. Additionally, the pole is equipped with four hooks, which not only facilitate the simultaneous administration of multiple IV bags but also support a total weight capacity of up to 15kg. This robust design accommodates a variety of medical necessities, making the IV pole a versatile and indispensable tool on any stretcher bed.

- IV Pole Prevision: The IV pole prevision on stretcher beds is a thoughtfully designed feature that significantly enhances the functionality and versatility of medical stretchers. Strategically placed at each of the four corners of the stretcher, these previsions allow for the placement of IV poles wherever most convenient or necessary based on the patient’s position and medical requirements. Each provision is equipped with a specialized switch mechanism that securely locks the infusion rod in place once it is inserted and the switch is closed. This ensures that the IV pole remains stable and fixed, preventing any unwanted movement that could disrupt the administration of IV fluids or medications. The availability of four different locations for IV pole placement not only improves accessibility for medical staff but also adapts to varying clinical scenarios, ensuring that patient care is both efficient and adaptable to individual needs. This design consideration enhances the stretcher’s utility, making it an invaluable asset in dynamic healthcare environments.

- Oxygen Cylinder Holder: The oxygen cylinder holder on stretcher beds is a meticulously designed feature that enhances the stretcher’s utility, particularly in emergency and critical care situations. Equipped with two adjustable support rings, this holder can securely accommodate oxygen cylinders of various sizes. These support rings can be easily adjusted to fit the diameter of different oxygen cylinders, ensuring that they are held firmly in place during transport. This adaptability is crucial as it allows medical personnel to have immediate and reliable access to oxygen, which is essential for patient care in numerous medical emergencies. The versatility provided by the adjustable rings means that healthcare facilities can use the same stretcher for different scenarios and patient needs without the concern of cylinder compatibility. This design not only improves the stretcher’s functionality but also enhances safety by preventing the oxygen cylinder from moving or falling during maneuvers, thereby ensuring a stable and safe environment for both the patient and medical staff.

- Mattress: The mattress of stretcher beds is designed to provide maximum comfort and support to patients, especially during prolonged periods of lying down. At the core of the mattress lies a soft sponge material, chosen for its ability to conform to the patient’s body shape, thus distributing weight evenly and reducing pressure points. This is crucial for preventing bedsores and enhancing patient comfort. Covering this sponge is a waterproof, breathable mattress cover, which plays a vital role in maintaining hygiene and comfort. The waterproof aspect of the cover ensures that any spills or bodily fluids do not seep into the sponge, thus preventing bacterial growth and making the mattress easy to clean and disinfect. Additionally, the breathability of the cover allows air to circulate, helping to regulate temperature and moisture, which is particularly beneficial in maintaining skin health and comfort. Moreover, the mattresses are available in various thicknesses, allowing medical facilities to choose according to specific patient needs or comfort preferences. This flexibility in style and thickness makes these mattresses highly adaptable and suited for a wide range of medical and healthcare applications.

BASE

Integrated utility tray to store the patient’ s belongings and medical supplies.

DESIGN

Clear arrow symbols on the stretcher body to instruct the user to operate. Clear scale.

PP SIDE RAIL

Multi-functional rotary PP side rails can be laid out on abed positioned next to the stretcher to act as a transfer board for easy and quick transfer. Fixable at horizontal level, where patient’ s arm can be placed on for the administration of transfusion or other treatment.

OXYGEN CYLINDER HOLDER

Two adjustable support rings are used to hold oxygen cylinders of different sizes.

DIRECTIONAL WHEEL SYSTEM

Retractable 5th wheel provides effortless directional movement and cornering. Pull down so that the guide wheel lands, and the whole stretcher can only go straight. Down the other side to turn.

Reviews

There are no reviews yet.